Hey kids, ever wondered which motor is used in a lathe machine? Well, you’re in the right place because we’re about to dive into the world of lathes and uncover the motor that makes them tick!

Picture this: you’re in a workshop surrounded by tools and machinery, and there, right in the middle, stands a lathe machine. But have you ever wondered what makes it spin and shape those pieces of metal or wood? It’s all thanks to a special kind of motor specifically designed for lathes.

So, what kind of motor is it, you ask? Drumroll, please… It’s called an induction motor! This motor is commonly used in lathes due to its reliable performance and efficiency. But how does it work? Well, let’s find out in the next paragraph.

At its core, an induction motor generates rotating magnetic fields that help drive the lathe machine. Think of it like a hidden force that makes everything come to life. The rotation of the magnetic field interacts with the rotor, which is the spinning part of the motor, causing it to turn and power the lathe. Pretty cool, right?

In conclusion, the motor used in a lathe machine is known as an induction motor. It’s responsible for the spinning action that allows lathes to shape various materials. So the next time you see a lathe machine in action, remember the mighty induction motor working behind the scenes to make it all possible!

In a lathe machine, an electric induction motor is typically used. Induction motors are widely used for their high efficiency, reliability, and low-cost maintenance. These motors provide the necessary power to drive the various components of the lathe machine, including the spindle, feed, and coolant pumps. They are designed to handle the continuous operation and heavy-duty workloads required in a lathe machine. Induction motors are a popular choice due to their ability to deliver consistent speed and torque, making them highly suitable for lathe machine applications.

The Motor Types Used in Lathe Machines: A Comprehensive Guide

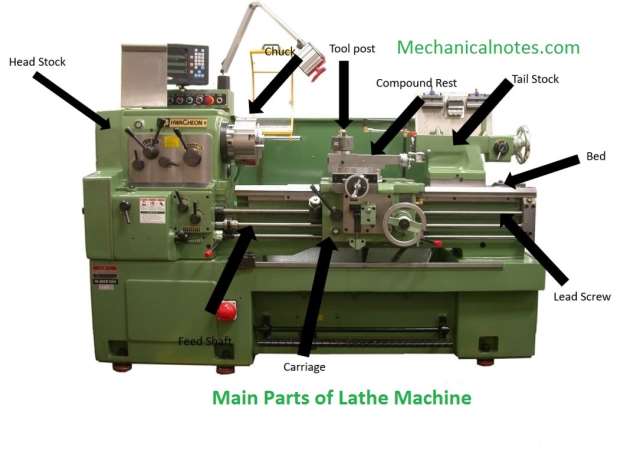

Lathe machines are an essential tool in the manufacturing industry, used for various operations such as cutting, sanding, drilling, and turning. A crucial component of a lathe machine is its motor, which provides the power and control required for precision machining. In this article, we will explore the different types of motors used in lathe machines, their features, advantages, and applications. Whether you are a seasoned machinist or a beginner interested in learning more about lathe machines, this guide will provide you with valuable insights.

Types of Motors Used in Lathe Machines

When it comes to the motors used in lathe machines, there are several options available, each with its unique characteristics and suitability for specific applications. Let’s explore the different types of motors commonly employed in lathe machines:

1. AC Induction Motor

AC induction motors are widely used in lathe machines due to their reliability, simplicity, and cost-effectiveness. These motors operate based on electromagnetic induction principles, where an alternating current in the stator windings creates a rotating magnetic field. The rotating magnetic field induces current in the rotor, causing it to rotate. AC induction motors offer excellent torque and speed control, making them suitable for a wide range of lathe machine operations.

AC induction motors are known for their high efficiency, low maintenance requirements, and long service life. They are capable of providing ample power for heavy-duty machining while maintaining precise control over rotational speed. These motors can be found in both single-phase and three-phase configurations, with three-phase motors being more common in industrial lathe machines.

Advantages of AC Induction Motors:

- Reliable and durable

- Cost-effective

- Efficient power transmission

- Excellent torque and speed control

2. Brushless DC Motor

Brushless DC motors, also known as BLDC motors, are becoming increasingly popular in lathe machines due to their high efficiency, precise speed control, and compact size. Unlike AC induction motors, BLDC motors do not require brushes and commutators for operation, resulting in reduced maintenance needs and longer service life.

BLDC motors operate using electronic commutation, where the rotor’s position is detected using sensors, and the stator windings are energized accordingly to produce smooth rotation. These motors offer excellent torque characteristics, making them ideal for applications that require high starting torque and accurate speed control.

Advantages of Brushless DC Motors:

- High efficiency

- Low maintenance requirements

- Precise speed control

- Compact and lightweight design

3. Stepper Motor

Stepper motors are another type of motor commonly used in lathe machines, especially for applications that require precise positioning and control. Stepper motors operate by converting electrical pulses into mechanical movement, rotating the shaft in discrete steps. These motors offer excellent positional accuracy, allowing machinists to achieve precise cuts, threads, and other intricate operations.

Stepper motors provide reliable and repeatable motion control, making them ideal for tasks like thread cutting, tapping, and other operations that require accurate positioning. They are commonly used in lathe machines for CNC (Computer Numerical Control) applications, where precise programming and control are essential.

Advantages of Stepper Motors:

- Precise positional control

- Repeatable and reliable motion

- Suitable for CNC applications

- No need for additional feedback devices

4. Servo Motor

Servo motors are advanced motors commonly found in high-end lathe machines that require precise and dynamic control. These motors operate using a closed-loop control system, where feedback sensors continuously monitor the rotor’s position and adjust the stator windings accordingly to maintain accurate motion. Servo motors provide high torque, speed, and acceleration capabilities, making them suitable for demanding machining applications.

Due to their excellent control characteristics, servo motors offer superior performance in terms of speed, position accuracy, and responsiveness. They are commonly used in CNC lathe machines and other high-precision applications that require rapid and precise tool movements.

Advantages of Servo Motors:

- Precise control over speed, position, and torque

- High dynamic performance

- Excellent responsiveness

- Optimal for high-precision machining

Determining the Right Motor for Your Lathe Machine

When choosing the motor for your lathe machine, several factors need to be considered, including the specific machining tasks, the desired level of precision, and the available power supply. Here are some tips to help you determine the right motor for your lathe machine:

1. Define Your Machining Requirements:

Identify the specific operations you will be performing on your lathe machine. Different machining tasks may require different levels of torque, speed control, and positional accuracy. Understanding your requirements will help you choose a motor that meets your machining needs.

2. Consider Power Supply:

Check the power supply available in your workspace. AC induction motors are commonly used in lathe machines because they can run on both single-phase and three-phase power. However, if you require precise speed control or have limited power supply options, a brushless DC motor or a servo motor may be a better choice.

3. Assess Your Budget:

Consider your budget and evaluate the cost-effectiveness of different motor options. AC induction motors are generally the most affordable option, while brushless DC motors and servo motors may be more expensive but offer advanced control capabilities. Choose a motor that balances your requirements with your budget.

4. Consult with Experts:

If you are unsure about the motor selection process or have specific requirements, don’t hesitate to consult with lathe machine experts or manufacturers. They can provide valuable guidance and help you choose the right motor for your specific needs.

Conclusion

Choosing the right motor for your lathe machine is a critical decision that can significantly impact the performance and efficiency of your machining operations. Understanding the different types of motors available and their respective features is essential for making an informed decision. Whether you opt for an AC induction motor, a brushless DC motor, a stepper motor, or a servo motor, each has its own advantages and applications. By considering your machining requirements, power supply, budget, and seeking expert advice, you can select the motor that best suits your needs, ensuring optimal performance and precision in your lathe machine operations.

Key Takeaways: Which Motor is Used in Lathe Machine?

- Most lathe machines use an electric motor.

- The motor used in a lathe machine is typically an induction motor.

- Induction motors are chosen for their reliability and durability.

- The power of the motor depends on the size and type of the lathe machine.

- Some lathe machines may also use a variable speed motor for increased versatility.

Frequently Asked Questions

Welcome to our FAQ section on the motors used in lathe machines. Below, you’ll find some commonly asked questions about the motors in these machines along with detailed answers. If you’ve ever wondered about the type and function of the motor in a lathe machine, you’re in the right place. Read on to learn more!

1. What is the purpose of the motor in a lathe machine?

The motor in a lathe machine is responsible for rotating the workpiece or the cutting tool. It provides the necessary power and control to achieve the desired speed and precision in the turning process. Without the motor, it would be impossible to perform the cutting and shaping tasks that a lathe machine is designed for.

Additionally, the motor provides the torque required to overcome the resistance of the material being turned and maintain a consistent rotational speed. It also allows for speed adjustments, allowing the operator to work with different materials and achieve different finishes.

2. What type of motor is typically used in lathe machines?

The most common type of motor used in lathe machines is the induction motor. Induction motors are widely used in various industrial applications due to their reliability, durability, and efficiency. These motors work on the principle of electromagnetic induction, where electrical energy is converted into mechanical energy.

Induction motors are preferred in lathe machines because they can provide a wide range of operating speeds, are relatively easy to control, and require minimal maintenance. They can also handle heavy loads and provide the necessary torque for cutting and shaping tasks, making them ideal for the demanding operations performed by lathe machines.

3. What are the key factors to consider when selecting a motor for a lathe machine?

When selecting a motor for a lathe machine, several factors need to be taken into consideration. The primary factors to consider include the required speed range, torque requirements, power supply compatibility, and the type of work to be performed.

The speed range and torque requirements of the motor should match the specific needs of the lathe machine to ensure optimal performance. Power supply compatibility is also crucial, as the motor should be compatible with the available power source to avoid any electrical issues. Additionally, considering the type of work to be performed helps determine if additional features such as variable speeds or high torque capabilities are necessary.

4. Can a lathe machine use a single-phase motor?

While it is possible to use a single-phase motor in a lathe machine, it is not very common. Single-phase motors are generally used in smaller machines or home workshops, as they are less powerful and have limitations in terms of torque and speed control.

In industrial settings or larger workshops, three-phase induction motors are commonly used due to their superior performance, higher power output, and better speed control capabilities. These motors are more efficient and offer greater torque, making them better suited for the demanding tasks typically performed with a lathe machine.

5. Can the motor in a lathe machine be upgraded or replaced?

Yes, it is possible to upgrade or replace the motor in a lathe machine. However, it is important to ensure that the replacement motor is compatible with the machine’s power requirements, mounting system, and control mechanisms. Additionally, any motor modification or replacement should be done by a qualified professional to ensure proper installation and minimize the risk of damage or operational issues.

If you are considering upgrading or replacing the motor in your lathe machine, it is advisable to consult with a knowledgeable technician or an expert in the field to determine the best motor option for your specific machine and operational requirements.

Summary

When it comes to the motor used in a lathe machine, there are generally two types. The first type is the AC motor, which is commonly used in larger, industrial lathes. AC motors are powerful and can handle heavy-duty work. The second type is the DC motor, which is often found in smaller, hobbyist lathes. DC motors are more compact and easier to control. Both types of motors have their advantages and disadvantages, so it’s important to choose the one that best suits your needs and the type of work you’ll be doing.

Overall, understanding the type of motor used in a lathe machine is crucial for determining the machine’s capabilities and performance. Whether it’s an AC motor for heavy-duty work or a DC motor for smaller projects, the motor plays a significant role in the lathe machine’s functionality. So, be sure to consider your specific needs and choose a motor accordingly.

The post Which Motor Is Used In Lathe Machine? appeared first on The Habit of Woodworking.

source https://thehabitofwoodworking.com/2024/which-motor-is-used-in-lathe-machine/

No comments:

Post a Comment