Are you wondering what bandsaw blade you need for metal? Well, you’ve come to the right place! When it comes to cutting metal with a bandsaw, using the right blade is crucial for achieving clean and precise cuts. In this article, we’ll explore the different types of bandsaw blades available for metal cutting and help you find the perfect fit for your needs.

Now, you might be thinking, “Why does the type of blade matter?” Well, each blade is designed to handle specific materials and cutting tasks. Whether you’re working with thin sheets of aluminum or thick steel pipes, choosing the right bandsaw blade can mean the difference between frustration and success. So, let’s dive in and discover the various factors you should consider when selecting the perfect bandsaw blade for metal cutting.

But wait, don’t fret! We’ll break it down into simple terms and guide you through the process step by step. By the end of this article, you’ll be equipped with the knowledge to confidently choose the perfect bandsaw blade for your metal cutting projects. So, let’s get started and find the ideal blade that will make your metalworking adventures a breeze!

What Bandsaw Blade Do I Need for Metal?

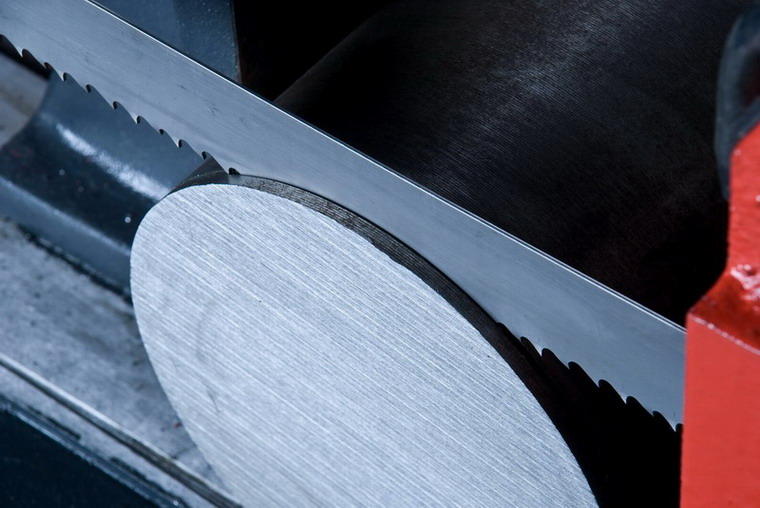

Metalworking is a precise craft that requires the right tools for the job. When it comes to cutting metal, a bandsaw is a popular choice due to its versatility and accuracy. However, choosing the correct bandsaw blade for metal can make all the difference in achieving clean, precise cuts. In this article, we will delve into the world of bandsaw blades for metal and explore the different types, sizes, and factors to consider in order to select the right blade for your specific needs.

1. Types of Bandsaw Blades for Metal

When it comes to cutting metal on a bandsaw, there are primarily two types of blades to consider: bi-metal blades and carbide-tipped blades. Bi-metal blades are made from two different types of steel, combining flexibility and durability. These blades are ideal for cutting a wide range of metals, including mild steel, stainless steel, alloy steel, and non-ferrous metals. On the other hand, carbide-tipped blades feature teeth with carbide tips, which provide exceptional hardness and cutting performance. These blades are specifically designed for cutting harder metals, such as hardened steel and titanium.

In addition to the blade type, the tooth pattern and pitch also play a crucial role in determining the cutting efficiency and quality. For general-purpose cutting, a variable tooth blade with a medium pitch (around 10-14 teeth per inch) is usually recommended. This tooth pattern allows for a balance between cutting speed and chip evacuation. However, for smoother and more precise cuts, a fine-tooth blade with a higher tooth count is preferred, while for faster, rough cuts, a coarse-tooth blade with a lower tooth count is more suitable.

2. Determining the Blade Length and Width

To ensure the bandsaw blade fits your machine and cutting needs, it is important to determine the correct length and width. The blade length is determined by the circumference of the bandsaw’s wheels or pulleys. You can measure the existing blade or refer to the manufacturer’s specifications to find the appropriate length. It is essential to choose a blade that fits snugly around the wheels to prevent any slipping or tracking issues.

The blade width, on the other hand, depends on the cutting capacity of your bandsaw and the thickness of the material you intend to cut. Each bandsaw has a maximum capacity it can handle, which is usually specified by the manufacturer. It is important to choose a blade width that falls within this range to ensure proper cutting performance and avoid unnecessary strain on the machine. Additionally, for straight cuts, the blade width should be at least 1/8 inch wider than the thickest material to allow for blade drift.

3. Factors to Consider When Selecting a Bandsaw Blade

Choosing the right bandsaw blade for metal involves considering several factors based on your specific application. Firstly, the type and thickness of the metal being cut play a crucial role. Harder metals require a more durable and heat-resistant blade, while softer metals can be cut with a blade featuring greater flexibility. It is also important to consider the surface finish required and the tolerance of the cut. For smooth, precise cuts, a blade with finer teeth is recommended, whereas for rough cuts or rapid material removal, a blade with coarser teeth is more suitable.

The speed at which you intend to cut also affects blade selection. Higher cutting speeds require blades with a higher tooth count to ensure efficient chip evacuation, while slower cutting speeds may benefit from blades with a lower tooth count to facilitate proper cooling and chip clearing. Additionally, the condition of the bandsaw, such as the tension, tracking, and alignment, should be regularly checked and adjusted to ensure optimal blade performance and longevity.

4. Tips for Cutting Metal with a Bandsaw Blade

To achieve the best results when cutting metal with a bandsaw blade, it is important to follow a few key tips. Firstly, ensure that the machine is properly set up and maintained to maximize cutting performance and blade life. Regularly lubricate the blade with cutting fluid or coolant to minimize heat buildup and extend blade life. When cutting, apply consistent, steady feed pressure to prevent blade binding and promote a smooth, even cut. It is also important to maintain proper blade speed and adjust the cutting rate based on the material being cut to avoid excessive blade wear or premature tooth dulling.

In conclusion, selecting the right bandsaw blade for metal is essential for achieving precise, clean cuts in your metalworking projects. Consider the type of blade, tooth pattern, blade length, and width based on the specific metal and cutting requirements. Take into account factors such as blade speed, surface finish, and tolerance, and follow proper cutting techniques to ensure optimal results. By choosing the correct bandsaw blade and employing best practices, you can enhance your metal cutting capabilities and achieve professional-level results in your metalworking endeavors.

Key Takeaways: What Bandsaw Blade Do I Need for Metal?

- Choose a bi-metal bandsaw blade for cutting metal.

- Consider the thickness and hardness of the metal when selecting the blade’s teeth per inch (TPI).

- Opt for a finer tooth pitch when cutting thin metal and a coarser pitch for thicker metal.

- Make sure the blade’s width fits the bandsaw’s specifications.

- Regularly lubricate the blade to prolong its lifespan and improve cutting performance.

Frequently Asked Questions

Welcome to our FAQ section where we will answer some common questions about choosing the right bandsaw blade for metal. Read on to find out everything you need to know!

1. What factors should I consider when choosing a bandsaw blade for cutting metal?

When choosing a bandsaw blade for metal, there are a few important factors to consider:

Firstly, you need to think about the type of metal you will be cutting. Different metals require different blade types, as they have varying hardness levels. High-speed steel blades are great for general purpose cutting, while bi-metal blades are ideal for tougher metals like stainless steel and tool steel.

You should also consider the thickness of the metal you’ll be cutting. Thicker metals require blades with fewer teeth per inch (TPI) for faster cutting, while thinner metals need blades with more TPI for smoother cuts.

2. Can I use the same bandsaw blade for cutting different types of metal?

While it is possible to use the same blade for cutting different types of metal, it’s not recommended for optimal results.

Each metal has its own unique characteristics, such as hardness and composition, which can affect the performance of the blade. Using the appropriate blade for each metal will ensure cleaner cuts, reduce the risk of blade damage, and prolong the life of the blade.

3. How can I determine the correct blade width for cutting metal?

When determining the correct blade width for cutting metal, you need to consider the radius of the smallest curve you’ll be cutting.

A general rule of thumb is to select a blade width that is at least three times the radius of the curve. This will allow the blade to make smooth, accurate cuts without excessive flexing or breaking. If you’ll be cutting straight lines or making long, straight cuts, a wider blade will provide more stability and reduce blade deflection.

4. How often should I replace my bandsaw blade when cutting metal?

The frequency of blade replacement depends on various factors, such as the type of metal being cut, the quality of the blade, and the intensity of the cutting job.

As a general guideline, regular inspection of the blade is essential. Look for signs of wear, such as dull teeth or damage. If the blade is not performing as well as it used to or if there are visible signs of wear, it’s time to replace it. Remember that using a worn-out blade can lead to poor cuts, increased risk of accidents, and shorter blade life.

5. Are there any safety precautions I should take when using a bandsaw blade for cutting metal?

Yes, there are a few important safety precautions to follow when using a bandsaw blade for cutting metal:

First and foremost, always wear appropriate Personal Protective Equipment (PPE), including safety glasses, gloves, and a face shield, to protect yourself from metal chips and debris.

Make sure the bandsaw is properly set up and the blade is appropriately tensioned before use. Follow the manufacturer’s instructions for blade installation and adjustment.

While operating the bandsaw, maintain a safe distance from the blade and use push sticks or other tools to guide the metal through the cut. Never use your hands to feed the material.

Finally, always adhere to proper blade handling and disposal procedures to prevent injuries and minimize environmental impact.

Summary

So, if you want to cut metal with a bandsaw, here’s what you need to know. Firstly, choose the right blade type, such as bi-metal or carbide-tipped, based on your specific needs. Next, consider the tooth pitch, with fewer teeth for thicker metals and more teeth for thinner metals. Finally, pay attention to the blade width, selecting a narrower or wider blade depending on the intricacy of your cuts.

In addition, don’t forget to adjust the speed of your bandsaw according to the thickness and hardness of the metal. Remember to wear safety gear and take proper precautions while working with a bandsaw. With these tips in mind, you’ll be able to confidently choose the right bandsaw blade for your metal cutting needs!

source https://thehabitofwoodworking.com/2023/what-bandsaw-blade-do-i-need-for-metal/

No comments:

Post a Comment