Want to know why lathes can be so dangerous? Well, let me tell you! Lathes may seem harmless at first glance, but they can pose serious risks if not used properly. So, what makes them dangerous? Let’s find out!

You see, lathes are powerful machines that shape and cut materials with high precision. They have spinning parts, sharp tools, and considerable force, combining into a potentially hazardous mix. If not handled with caution, accidents can happen.

But don’t worry, my friend, I’m here to guide you through the potential dangers and teach you how to stay safe while using a lathe machine. So, buckle up and let’s dive into the fascinating world of lathe safety!

Lathes can be dangerous due to several factors. First, their high-speed rotating parts can cause serious injuries if not handled properly. Secondly, sharp cutting tools used with lathes can pose a risk if not used with caution. Inadequate training or lack of safety protocols also contribute to accidents. It is important to prioritize safety by wearing protective gear, following proper operating procedures, and receiving thorough training before operating a lathe machine.

Why Are Lathes So Dangerous?

When it comes to working with machinery, safety should always be a top priority. This is especially true when it comes to lathes, which are powerful tools used to shape and cut various materials. While lathes are incredibly useful for many applications, they can also pose significant risks if not used properly. In this article, we will explore why lathes are so dangerous and provide valuable information on how to stay safe while operating them.

The Dangers of Lathes: Understanding the Risks

1. Rotating Parts: Lathes have various rotating parts, such as the chuck, tailstock, and cutting tools. These components can spin at high speeds, posing a significant risk of entanglement or contact with moving parts. If a person’s hand or clothing gets caught in the rotating parts, it can result in severe injuries, such as fractures, amputations, or even death.

2. Flying Debris: Lathes generate a large amount of force, causing materials to spin rapidly. This can lead to the ejection of small fragments or chips, often at high velocities. These flying debris can cause serious injuries if they come into contact with the operator or nearby individuals. Without proper protective equipment, such as safety goggles or face shields, the risk of eye injuries from the flying debris increases significantly.

3. Tool Accidents: Using cutting tools on a lathe requires skill and precision. If not used correctly, there is a high probability of tool accidents, including tool breakage, tool binding, or tool holder failure. These incidents can result in the uncontrolled release of stored energy, leading to sudden movement or ejection of the workpiece, which can cause harm to the operator or bystanders.

1. Lack of Proper Training and Knowledge

One of the primary reasons why lathes can be dangerous is the lack of proper training and knowledge. Operating a lathe without the necessary understanding of its components, functions, and safe operating procedures can significantly increase the risk of accidents. Without proper training, workers may not be aware of the potential hazards, how to use safety features correctly, or the precautions necessary to prevent accidents.

It is crucial for individuals operating lathes to receive comprehensive training from qualified instructors. This training should cover basic safety practices, machine-specific operating procedures, and maintenance requirements. By educating operators properly, companies can reduce the likelihood of accidents and create a safer working environment.

Furthermore, ongoing refresher courses and regular safety meetings should be conducted to ensure that operators stay up-to-date with the latest safety protocols. By fostering a culture of safety and continuous learning, the risks associated with operating lathes can be effectively minimized.

2. Inadequate Safety Measures and Equipment

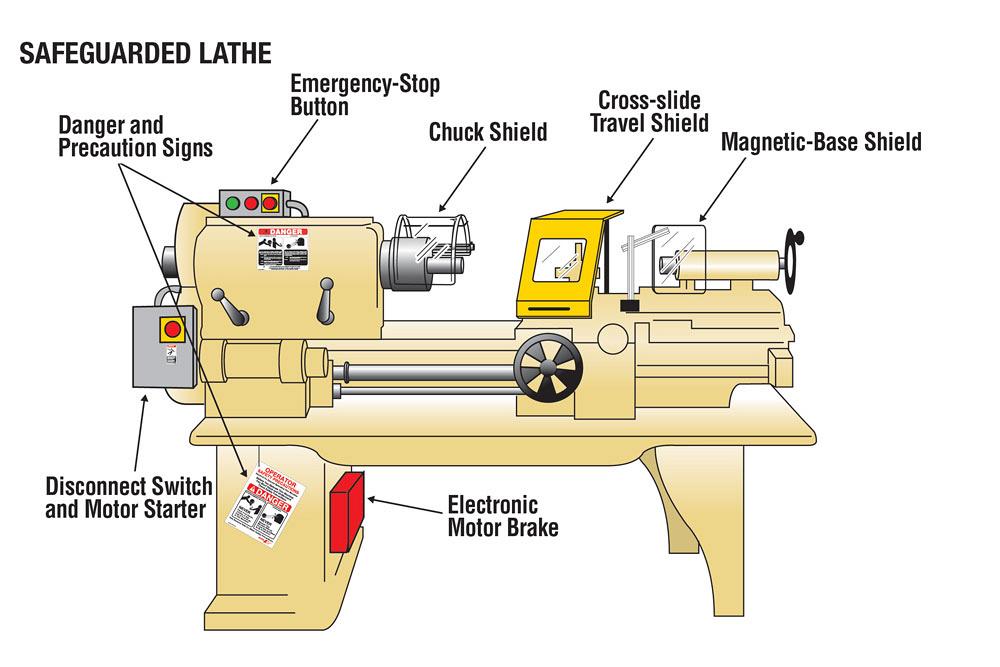

Another reason why lathes can be dangerous is the absence or improper use of safety measures and equipment. Every lathe should be equipped with appropriate safety features, such as emergency stops, interlocks, and guarding. These measures are designed to mitigate risks, protect operators, and prevent accidents from occurring.

Additionally, personal protective equipment (PPE), such as goggles, gloves, and aprons, should be provided and used by anyone operating a lathe. PPE serves as a final line of defense, providing a physical barrier that can shield the operator from potential hazards.

However, it is not enough to simply have safety measures and equipment in place. Regular inspections and maintenance should be conducted to ensure that all safety features are functioning correctly. Any damaged or malfunctioning components should be repaired or replaced promptly. Additionally, operators must be trained on the correct usage and care of PPE to ensure its effectiveness.

3. Failure to Follow Safety Guidelines

One of the most significant contributors to lathe accidents is the failure to follow safety guidelines. Whether due to negligence, complacency, or ignorance, disregarding safety protocols can have severe consequences. Operators must understand that any deviation from established safety guidelines can put themselves and others at risk.

It is essential for operators to familiarize themselves with the machine’s operating manual and adhere to the instructions provided. This includes understanding the machine’s capacity, performing regular maintenance checks, using the correct cutting tools, and following safe work practices.

Supervisors and management also play a vital role in promoting a safe working environment. They should encourage open communication, provide clear safety policies, and ensure that operators are following established guidelines. Regular safety audits and inspections should be conducted to identify any potential hazards or areas for improvement.

Staying Safe While Operating Lathes: Tips and Best Practices

While lathes may present inherent risks, there are steps that can be taken to minimize these dangers and ensure a safe work environment. Here are some tips and best practices for staying safe while operating lathes:

1. Receive proper training: Ensure that all operators receive comprehensive training on lathe operation, safety procedures, and maintenance requirements.

2. Use appropriate personal protective equipment: Provide and enforce the use of PPE, such as safety goggles, gloves, and aprons, to protect against potential hazards.

3. Follow safety guidelines: Adhere to the lathe’s operating manual and established safety protocols. This includes regular maintenance checks, using the correct cutting tools, and practicing safe work habits.

4. Keep the work area clean and organized: Maintain a clutter-free work area to reduce the risk of accidents caused by tripping or falling objects.

5. Always use the lathe’s safety features: Familiarize yourself with the emergency stops, interlocks, and guarding, and use them as intended.

6. Perform regular inspections and maintenance: Regularly inspect the lathe to ensure that all components and safety features are in good working condition. Address any issues promptly.

7. Communicate and report hazards: Encourage open communication among operators and supervisors, and promptly report any potential hazards or safety concerns.

By following these tips and best practices, operators can reduce the likelihood of accidents and create a safer work environment when using lathes.

Conclusion

Operating lathes can be dangerous if not approached with caution and proper safety measures. The risks associated with lathes include entanglement with rotating parts, flying debris, and tool accidents. However, by addressing the underlying causes of these dangers, such as inadequate training, improper safety measures, and failure to follow guidelines, the risks can be effectively mitigated.

It is crucial for operators to receive comprehensive training, use appropriate safety measures and equipment, and follow established safety guidelines. By adopting best practices and fostering a culture of safety, the hazards associated with operating lathes can be minimized, creating a safer working environment for all.

Key Takeaways: Why Are Lathes So Dangerous?

- Lathes can be dangerous due to their rotating parts and high-speed operation.

- They can cause severe injuries if not used properly and without proper safety precautions.

- Operators must always wear appropriate personal protective equipment (PPE) while operating a lathe.

- Understanding and following the lathe’s operating manual is crucial for safety.

- Proper training and supervision are necessary to minimize the risk of accidents.

Frequently Asked Questions

Welcome to our FAQ section on the topic of lathe safety! Lathes are powerful and versatile machines used in various industries. While they are incredibly useful, they can also be hazardous if not handled with care. In this section, we will address common questions regarding the dangers associated with lathes and how to mitigate the risks. Let’s dive in!

1. How do lathes pose a safety risk?

Lathes can be dangerous due to their high rotational speeds and the sharp tools they employ. Operating a lathe involves handling heavy materials that are spun rapidly, creating the risk of objects getting caught, leading to severe injuries. The sharp cutting tools used can also cause accidents if not used correctly or if safety measures are overlooked.

To ensure safety while using lathes, proper training is crucial. Understanding the machine’s mechanics, following safety protocols, and wearing personal protective equipment (PPE) such as safety glasses and gloves can greatly reduce the risk of accidents.

2. What are the common injuries associated with lathes?

Operating a lathe without proper precautions can result in various injuries. Some common ones include lacerations from contact with sharp tools or spinning parts, crush injuries from being caught between moving components, and eye injuries caused by flying debris or metal shavings.

To prevent such injuries, operators should always wear appropriate PPE, inspect machines for any defects before use, and ensure workpieces are properly secured. Regular maintenance and machine checks can help identify potential hazards and address them promptly.

3. How can I protect myself when operating a lathe?

Protecting yourself when using a lathe is of utmost importance. Always wear the recommended PPE, including safety glasses, gloves, and closed-toe shoes. Avoid wearing loose clothing or jewelry that can get entangled in the lathe’s moving parts. Also, ensure the work area is well-lit and free from clutter to minimize the risk of tripping or losing balance.

In addition, familiarize yourself with the machine’s safety features and emergency stop button, and always follow proper lockout/tagout procedures when performing maintenance or repairs. Remember, it’s crucial to receive comprehensive training on lathe operation and safety practices before using the equipment.

4. Are there any safety measures to consider before starting a lathe?

Prior to starting a lathe, there are several safety measures to keep in mind. Inspect the machine to ensure it is in proper working condition – check for loose parts, damaged cords, or any signs of malfunction. Make sure the cutting tools are sharp and properly secured.

Furthermore, always check that the workpiece is securely fastened in place and that all necessary adjustments have been made before turning on the lathe. This includes setting the correct speed and ensuring the tool rest and tailstock are properly positioned. By taking these precautions, you can significantly reduce the risk of accidents while operating a lathe.

5. How can employers promote lathe safety in the workplace?

Employers play a vital role in promoting lathe safety. They should ensure that employees receive comprehensive training on lathe operation and safety protocols. Safety procedures should be clearly communicated and readily available in written form.

Regular inspections of machinery, coupled with routine maintenance and repairs, can help identify potential hazards and prevent accidents. Employers should also encourage open communication between workers and management, allowing employees to report any safety concerns or incidents. By fostering a culture of safety awareness, employers can create a safe working environment for all lathe operators.

Summary

Lathes can be dangerous because they have sharp cutting tools and move very fast. It’s important to always wear protective gear to avoid injuries. Proper training is crucial to operate lathes safely and avoid accidents. It’s also essential to keep the workspace clean and organized to prevent accidents. Finally, being mindful of your surroundings and staying focused while using a lathe can help prevent injuries and keep you safe.

Remember, lathes can be dangerous, but by taking precautions, following safety guidelines, and using common sense, accidents can be avoided. Stay safe!

source https://thehabitofwoodworking.com/2023/why-are-lathes-so-dangerous/

No comments:

Post a Comment