Thinking about installing EPDM roofing on your plywood? Wondering if it can be done directly? Well, you’ve come to the right place! In this article, we’ll dive into the world of EPDM (Ethylene Propylene Diene Monomer) roofing and shed some light on whether it can be installed directly on plywood. So, let’s get started and find out if EPDM and plywood make a perfect match!

EPDM is a popular roofing material known for its durability and flexibility. People often wonder if they can skip a step and install EPDM directly on plywood without any additional layers or underlayment. It’s a valid question, and we’re here to help you find the answer. So, buckle up and let’s delve into the world of EPDM roofing and its compatibility with plywood.

Installing EPDM directly on plywood may seem tempting, but is it the right approach? We’ll explore the advantages and disadvantages of both options, weigh the pros and cons, and provide you with valuable insights to help you make an informed decision. So, let’s roll up our sleeves and take a closer look at whether EPDM can be installed directly on plywood or if there’s more to consider.

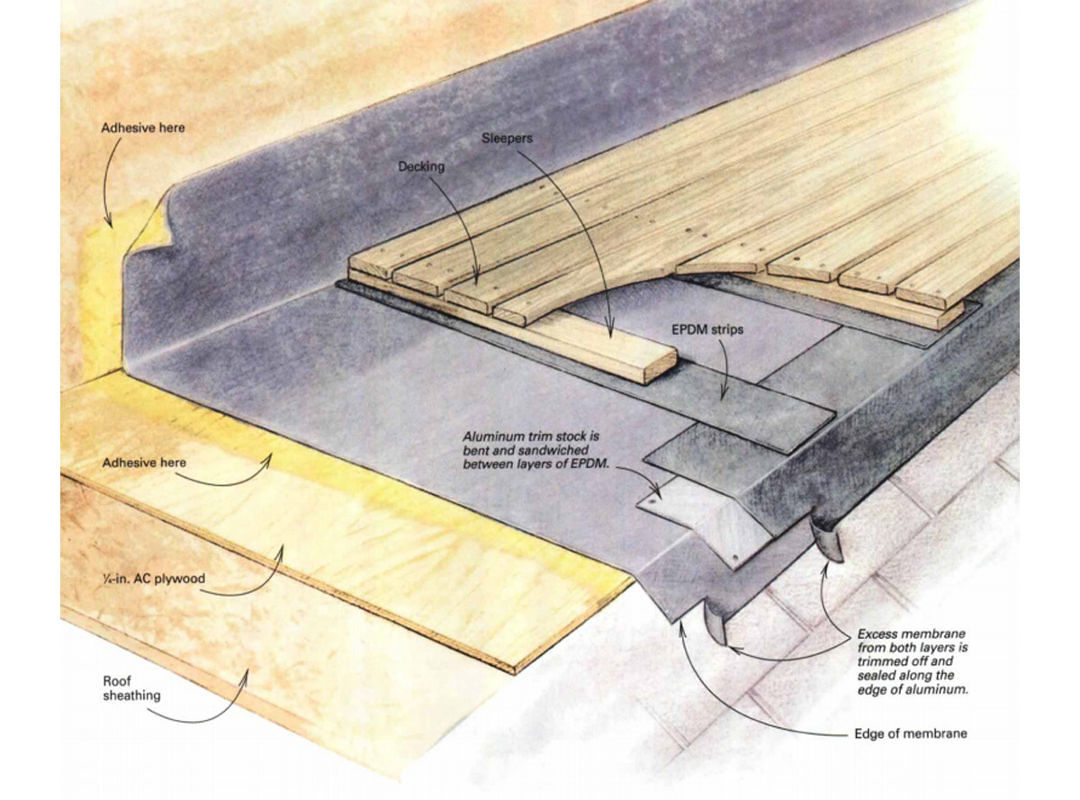

Can EPDM be installed directly on plywood? Many experts recommend installing a layer of underlayment material, such as a rubber membrane or roofing felt, between the EPDM membrane and the plywood. This helps to protect the EPDM from any potential damage or moisture penetration. It is important to ensure a proper installation to maximize the lifespan and effectiveness of the EPDM roofing system.

For a durable and long-lasting EPDM roof, consult with a professional roofing contractor to determine the best installation methods for your specific project.

Can EPDM be Installed Directly on Plywood?

When it comes to installing EPDM (ethylene propylene diene terpolymer) roofing, one common question that arises is whether it can be installed directly on plywood. EPDM is a popular roofing material known for its durability and low maintenance. In this article, we will explore whether EPDM can be installed directly on plywood and provide detailed information on the best practices for EPDM installation.

Benefits of Installing EPDM Directly on Plywood

There are several benefits to installing EPDM directly on plywood. Firstly, plywood provides a solid and stable surface for the EPDM to adhere to, ensuring a secure and long-lasting installation. Additionally, plywood helps to distribute the weight of the EPDM evenly, reducing the risk of structural damage. Moreover, installing EPDM directly on plywood can also act as an additional layer of insulation, improving energy efficiency. Lastly, plywood can help to prevent moisture intrusion and protect the underlying structure from water damage.

Choosing the Right Plywood

When installing EPDM directly on plywood, it is crucial to select the right type of plywood to ensure a successful installation. The plywood should be exterior-grade and specifically designed for roofing applications. It should be smooth, flat, and free from any defects such as knots, cracks, or warping. It is recommended to use plywood with a minimum thickness of 15/32 inch (12 mm). Additionally, the plywood should be properly primed and sealed to protect it from moisture and prolong its lifespan. By choosing the right plywood, you can ensure the stability and longevity of your EPDM roof.

Preparation and Installation Process

Before installing EPDM directly on plywood, proper preparation is essential. The plywood surface should be clean, dry, and free from any debris or protruding nails. Any damaged or rotten plywood should be replaced to ensure a solid foundation. Once the surface is prepared, a primer should be applied to the plywood to improve adhesion. It is important to follow the manufacturer’s instructions when applying the primer. After the primer has dried, the EPDM can be rolled out onto the plywood surface, ensuring that it is cut to the appropriate size and properly positioned. The EPDM should then be secured in place using adhesive or fasteners, following the manufacturer’s guidelines.

During the installation process, it is crucial to pay attention to detail and ensure a proper overlap of the EPDM sheets to create a watertight seal. The edges and seams should be properly sealed to prevent any water infiltration. It is recommended to consult a professional or refer to manufacturer guidelines for the specific installation techniques and products to use. By following the proper preparation and installation process, you can ensure a successful installation of EPDM directly on plywood.

Maintenance and Tips for EPDM on Plywood Roofs

To maintain the longevity of an EPDM roof installed directly on plywood, regular inspections and maintenance are important. It is recommended to inspect the roof annually for any signs of damage or wear, such as punctures, cracks, or loose seams. Any debris or vegetation should be cleared from the roof surface to prevent standing water and potential damage to the EPDM. Regular cleaning with a mild detergent and soft brush can help remove dirt and stains. Additionally, it is important to avoid placing heavy objects or walking on the EPDM to prevent damage. Finally, it is advisable to consult with a professional roofer for any major repairs or if any concerns arise about the EPDM roof installed directly on plywood.

Conclusion

In conclusion, EPDM can indeed be installed directly on plywood. The benefits of this installation method include stability, insulation, and protection against moisture. However, it is crucial to choose the right type of plywood and follow proper preparation and installation processes. Regular maintenance and inspections are necessary to ensure the longevity of an EPDM roof installed on plywood. By adhering to these guidelines and seeking professional advice when needed, you can enjoy the benefits of a durable and low-maintenance EPDM roof on your plywood substrate.

The Advantages of EPDM Roofing

EPDM roofing offers a range of advantages that make it a popular choice for both residential and commercial applications. In this section, we will explore these benefits in detail and understand why EPDM roofing is a preferred option for many homeowners and building owners.

EPDM vs. Other Roofing Materials

EPDM is just one of the many roofing materials available in the market. In this section, we will compare EPDM with other popular roofing materials, such as asphalt shingles, metal, and PVC, to help you make an informed decision about which material is best suited for your roofing needs.

Tips for Maintaining an EPDM Roof

In this section, we will provide some valuable tips and guidelines to help you effectively maintain your EPDM roof. From inspections to cleaning techniques, these tips will ensure the longevity and performance of your EPDM roofing system.

Key Takeaways: Can EPDM be Installed Directly on Plywood?

- Yes, EPDM can be installed directly on plywood.

- However, it is recommended to use a suitable adhesive or bonding agent for better adhesion.

- EPDM provides excellent durability and resistance to weathering.

- Proper surface preparation is crucial before installation to ensure a secure and long-lasting bond.

- EPDM is commonly used for flat roofs, ponds, and other waterproofing applications.

Frequently Asked Questions

Installing EPDM directly on plywood is a common question among homeowners and DIY enthusiasts. In this section, we’ll address some important points related to this topic.

Q: Is it possible to install EPDM directly on plywood?

A: While it is technically possible to install EPDM directly on plywood, it is not recommended. EPDM rubber roofing requires a smooth and stable surface for proper installation and long-term performance. Plywood can expand and contract with changes in temperature and humidity, which can lead to problems such as cracking, bubbling, or even delamination of the EPDM membrane. To ensure a durable and watertight roof, it is best to use an appropriate underlayment or substrate beneath the EPDM.

When installing EPDM roofing, it is important to consult with a professional or follow the manufacturer’s guidelines to ensure proper installation and avoid potential issues that may arise from installing directly on plywood.

Q: What are the alternative options to installing EPDM directly on plywood?

A: If you have plywood as the base for your roofing project and want to install EPDM, there are alternative options to consider. One common approach is to use a roofing underlayment specifically designed for EPDM installations. These underlayments provide an extra layer of protection, helping to prevent damage caused by expansion and contraction of the plywood. Another option is to use a vapor barrier or a barrier board, which helps minimize moisture absorption and protect the EPDM membrane from potential damage.

Before proceeding with the installation, it is important to evaluate the condition of the plywood and ensure it is structurally sound. Any damaged or deteriorated plywood should be repaired or replaced before installing EPDM or any other roofing material.

Q: What are the benefits of using an underlayment when installing EPDM on plywood?

A: Using an underlayment when installing EPDM on plywood offers several benefits. First and foremost, it provides a smooth and stable surface for the EPDM membrane, reducing the risk of cracking or delamination. An underlayment can also help protect the EPDM from the expansion and contraction of the plywood, extending the lifespan of the roofing system. Additionally, underlayments can provide additional insulation and noise reduction properties, enhancing the overall performance and comfort of the roof.

When selecting an underlayment, it is important to choose one that is compatible with EPDM roofing systems and meets the necessary building code requirements. Consult with a roofing professional or review the manufacturer’s guidelines to determine the most suitable underlayment for your specific installation.

Q: Can I install EPDM on plywood if I use a vapor barrier?

A: While a vapor barrier can help reduce moisture absorption and protect the EPDM membrane from potential damage, it is still recommended to use an appropriate underlayment or substrate when installing EPDM on plywood. A vapor barrier alone may not provide the necessary smoothness and stability required for the EPDM installation. Combining a vapor barrier with an underlayment designed for EPDM roofing systems will help ensure a durable and long-lasting roof.

Follow the manufacturer’s guidelines and consult with a roofing professional to determine the best combination of materials for your specific installation.

Q: Are there any other considerations when installing EPDM on plywood?

A: Yes, there are a few additional considerations to keep in mind when installing EPDM on plywood. Proper surface preparation is crucial for a successful installation. This includes cleaning and priming the plywood to ensure proper adhesion of the EPDM membrane. Additionally, it is important to take into account local building codes, climate conditions, and manufacturer’s recommendations when planning the installation. Consulting with a roofing professional is highly recommended to ensure all relevant factors are considered for a successful EPDM installation on plywood.

By following the correct installation procedures and using the appropriate materials, EPDM can provide a durable, watertight, and long-lasting roofing solution, even when installed on plywood.

Summary

Installing EPDM directly on plywood is not recommended because plywood can expand and contract, causing the EPDM to crack. A proper base layer, such as insulation board, should be used instead, to ensure a long-lasting and durable installation. Additionally, EPDM should be installed by a professional to avoid any mistakes and ensure the best results.

In conclusion, it is important to follow the proper procedures when installing EPDM to ensure its longevity and effectiveness. By using the right base layer and relying on professional installation, you can enjoy the benefits of EPDM roofing for years to come.

source https://thehabitofwoodworking.com/2023/can-epdm-be-installed-directly-on-plywood/

No comments:

Post a Comment