Welcome to the world of lathes, where precision and craftsmanship meet creativity and ingenuity. So, why use a lathe dog? Let me break it down for you in simple terms.

You see, a lathe dog is a handy little tool that helps secure the workpiece firmly on the lathe. It’s like a trusty sidekick that keeps the material from slipping or spinning when you’re turning it.

Imagine you’re working on a woodworking project, or maybe you’re a budding metalworker. By using a lathe dog, you ensure that your workpiece stays in place, allowing you to shape and mold it precisely as you envision.

So, whether you’re a hobbyist or a professional, a lathe dog is a must-have tool to unleash the full potential of your lathe and bring your creations to life. Let’s dive deeper into the world of lathe dogs and all the wonders they can help you achieve!

Why Use a Lathe Dog: Unlocking the Power of Precision Machining

When it comes to precision machining, one tool that stands out is the lathe dog. This simple yet indispensable device has revolutionized the manufacturing industry by enabling machinists to achieve incredible accuracy and efficiency in their work. Whether you’re a professional machinist or a DIY enthusiast, understanding why to use a lathe dog can take your machining capabilities to the next level. In this article, we will explore the various benefits and practical applications of using a lathe dog, as well as provide some valuable tips for maximizing its potential.

Understanding the Function and Structure of a Lathe Dog

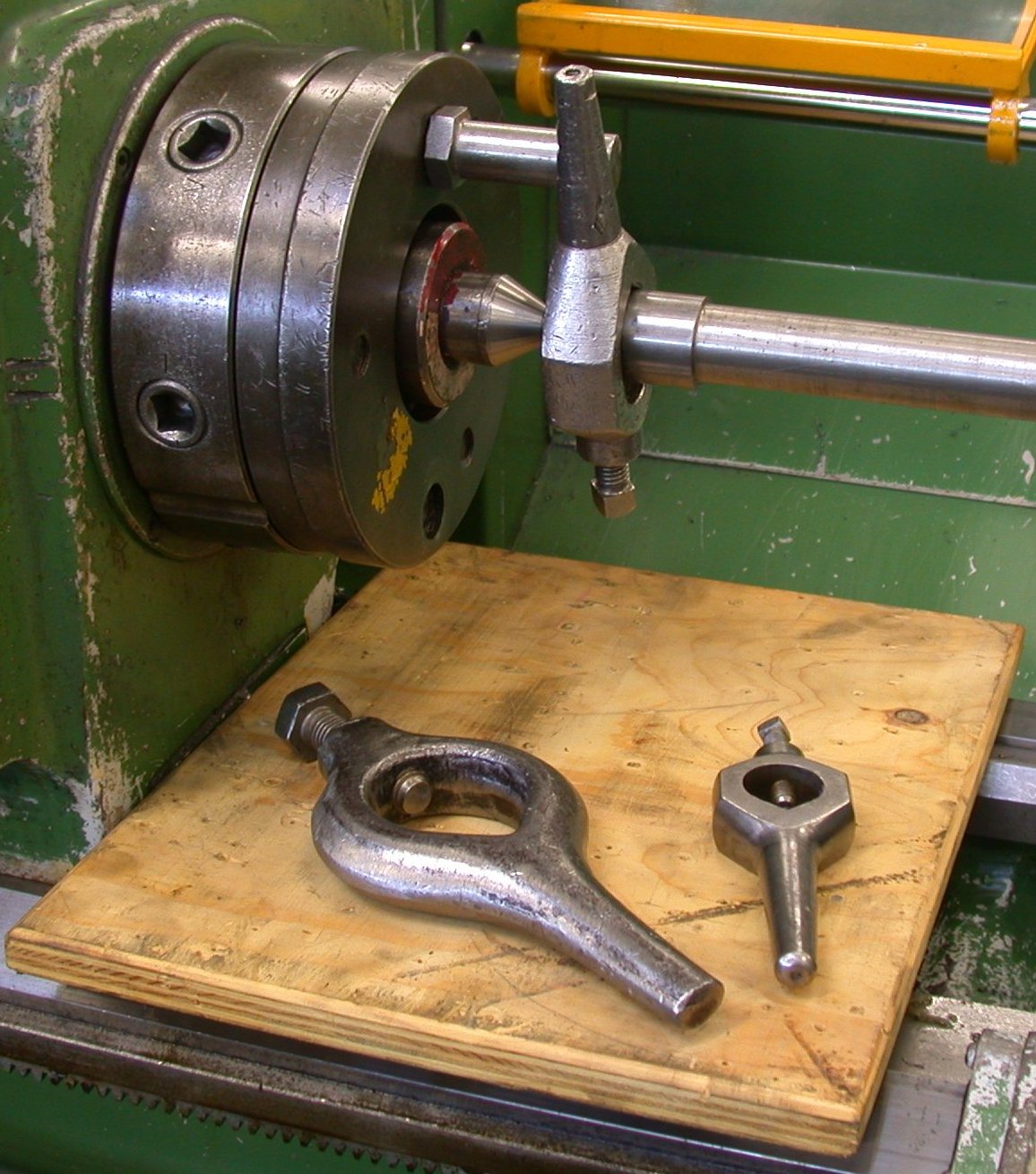

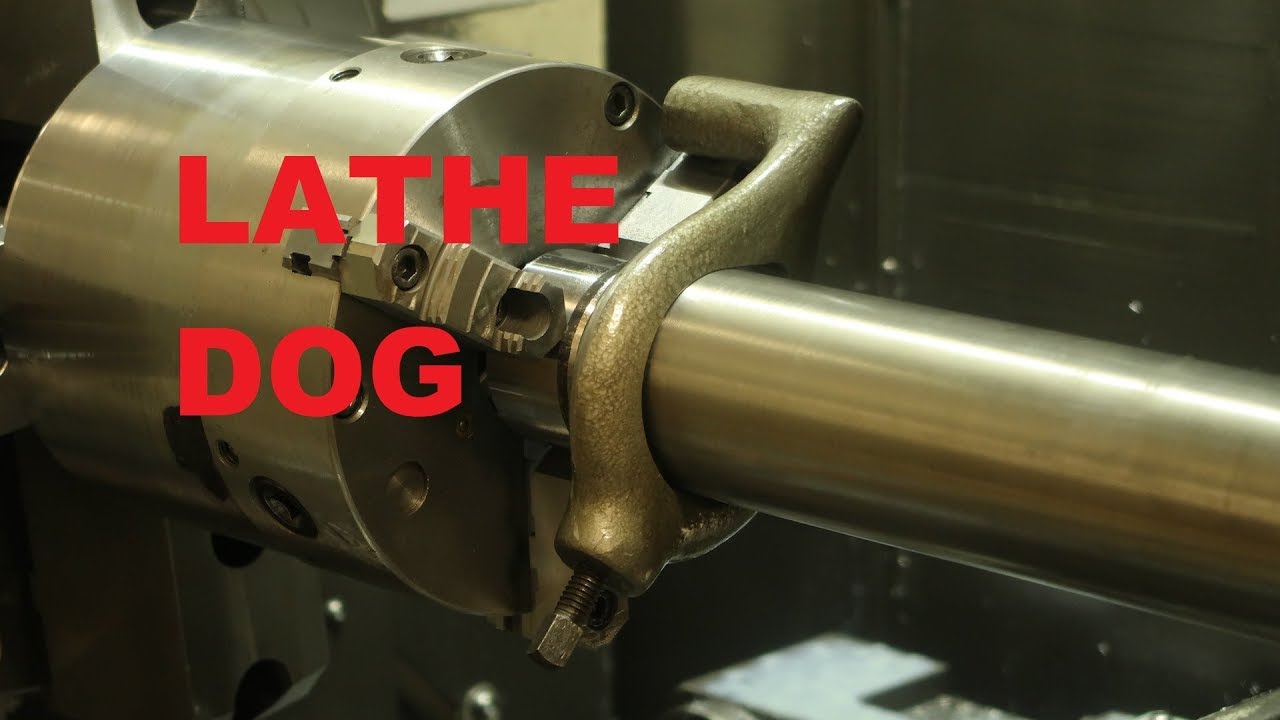

Before delving into the advantages of using a lathe dog, it’s essential to understand what it is and how it functions. A lathe dog, also known as a lathe carrier or a lathe driver, is a mechanical device used to secure and drive a workpiece on a lathe machine. It typically consists of a curved body with a projecting arm that engages with the workpiece. The arm is clamped onto the workpiece using a screw or lever mechanism, providing a secure connection that allows the lathe to rotate the workpiece with precision.

Lathe dogs are available in various designs, including bent tail, straight tail, and box tail. Each design has its own advantages and is suited for specific applications. Regardless of the design, the primary purpose of a lathe dog is to transmit the rotational force from the lathe spindle to the workpiece, enabling the machinist to shape and refine the workpiece according to their requirements. This versatility and functionality make the lathe dog an indispensable tool in precision machining.

The Benefits of Using a Lathe Dog

Now that we have a basic understanding of what a lathe dog is, let’s dive into the benefits of using one in your machining projects:

1. Enhanced Stability and Control:

One of the primary advantages of using a lathe dog is the enhanced stability and control it provides during the machining process. By securely clamping onto the workpiece, the lathe dog prevents any slippage or movement that could result in inaccuracies or imperfections. This stability allows machinists to work with confidence, knowing that they have full control over the positioning and movement of the workpiece.

In addition, the use of a lathe dog minimizes the risk of accidents or injuries caused by loose or unsecured workpieces. The secure connection between the lathe dog and the workpiece ensures that they move together as one unit, reducing the chances of unexpected movements that could endanger the operator or damage the workpiece.

2. Precise Machining:

When it comes to precision machining, every millimeter counts. The use of a lathe dog enables machinists to achieve exceptional accuracy and precision in their work. By securely clamping onto the workpiece, the lathe dog minimizes any movement or vibrations during the machining process, resulting in clean and accurate cuts, turns, and shapes.

In addition, the lathe dog’s adjustable clamping mechanism allows machinists to position the workpiece at the desired angle and orientation, ensuring that the machining operations are performed with precision. Whether you’re turning intricate details on a small component or working on a larger project, the lathe dog’s ability to maintain stability and control is essential for achieving the highest level of accuracy in machining.

3. Versatility and Flexibility:

Another significant advantage of using a lathe dog is its versatility and flexibility in accommodating different workpiece sizes and shapes. Whether you’re working with cylindrical, rectangular, or irregularly shaped workpieces, a lathe dog can securely clamp onto them and provide the necessary driving force for machining operations.

Furthermore, lathe dogs are available in various sizes and designs to suit different lathe machines and workpiece requirements. This means that regardless of the size or type of lathe you are using, you can find a lathe dog that fits perfectly and allows you to work on a wide range of projects with ease.

Practical Tips for Using a Lathe Dog Efficiently

Now that we understand the benefits of using a lathe dog let’s explore some practical tips that can help you make the most of this valuable tool:

1. Choose the Right Lathe Dog for the Job:

As mentioned earlier, lathe dogs come in various designs and sizes. It’s crucial to select the right lathe dog for the specific project you’re working on. Consider factors such as the size and shape of the workpiece, the type of machining operations required, and the compatibility with your lathe machine. Choosing the appropriate lathe dog will ensure optimal performance and accurate results.

2. Ensure Proper Alignment:

Before using a lathe dog, it’s essential to ensure that the workpiece is properly aligned and centered on the lathe machine. Securely position the workpiece and use a centering tool or dial indicator to confirm accuracy. Proper alignment will prevent any issues during the machining process and help achieve the desired precision and quality in your work.

3. Regularly Inspect and Maintain the Lathe Dog:

To ensure optimal performance and longevity, it’s essential to regularly inspect and maintain your lathe dog. Check for any signs of wear or damage, such as bent arms or loose clamping mechanisms, and replace or repair them as necessary. Additionally, lubricate any moving parts to prevent friction and ensure smooth operation.

Conclusion

Using a lathe dog is a game-changer in precision machining, offering enhanced stability, precise control, and versatility in working on various projects. By understanding the benefits and following the practical tips provided in this article, you can unlock the full potential of the lathe dog and take your machining skills to new heights. Embrace the power of this simple yet indispensable tool and watch your machining projects transform with unmatched accuracy and efficiency.

Key Takeaways: Why Use a Lathe Dog?

- Lathe dogs are used to hold and rotate irregularly shaped workpieces on a lathe.

- They provide a secure grip on the workpiece, preventing it from slipping or moving during machining.

- Using a lathe dog allows for precise and accurate turning, cutting, or shaping of the workpiece.

- They are particularly useful when working with long and slender workpieces that would otherwise be difficult to hold in place.

- Lathe dogs come in various sizes and designs to accommodate different types of workpieces and lathe configurations.

Frequently Asked Questions

Curious about why people use a lathe dog? Look no further! Below are some common questions answered in detail.

What is the purpose of using a lathe dog?

A lathe dog is a useful tool for securely holding a workpiece in a lathe machine. By attaching the dog to the workpiece and locking it into the lathe spindle, the dog acts as a driving mechanism. It rotates the workpiece as the lathe motor turns, allowing for precision shaping, cutting, or threading operations to be performed on the workpiece. Essentially, the lathe dog ensures stability and control during machining.

Without the lathe dog, it would be challenging to hold and rotate the workpiece consistently, leading to inconsistencies in cutting or shaping and potentially compromising the quality of the final product. Whether you are working on wood, metal, or plastic, the lathe dog’s purpose remains the same: to securely hold and rotate the workpiece in the lathe machine.

Can I use a lathe dog for any type of lathe machine?

The good news is that lathe dogs can be used with most types of lathe machines. Whether you have a bench lathe, engine lathe, or turret lathe, you can typically find a suitable lathe dog that matches the specifications of your machine. However, it is important to consider the size and design of the dog, as well as the compatibility with your lathe’s spindle and chuck.

For example, if you have a larger lathe machine with a powerful motor, you might need a heavier-duty lathe dog to handle the extra weight and torque. On the other hand, if you have a smaller lathe machine, a lighter and more compact lathe dog may be sufficient. It’s always a good idea to consult your lathe machine’s manual or seek guidance from a knowledgeable professional to ensure you choose the right lathe dog for your specific machine.

What are the advantages of using a lathe dog?

Using a lathe dog comes with several advantages. Firstly, it provides a secure grip on the workpiece, minimizing the risk of it slipping or turning unevenly during machining. This stability allows for precise and consistent cutting operations, resulting in a higher-quality finished product.

Secondly, the lathe dog enables the rotation of irregularly shaped workpieces that are difficult to hold with other methods. By gripping the workpiece at specific points using the dog’s teeth, it ensures efficient and controlled rotation, making intricate machining tasks more manageable.

Are there any limitations to using a lathe dog?

While a lathe dog is a versatile and helpful tool, it does have a few limitations. One limitation is that it requires the workpiece to have a suitable cylindrical shape with sufficient contact area for the dog’s teeth to grip securely. If the workpiece is irregularly shaped or lacks a suitable surface, alternative methods of gripping or supporting the workpiece may be necessary.

Additionally, lathe dogs rely on physical contact between the dog’s teeth and the workpiece surface, which can potentially leave marks or indentations on the finished product. This is particularly important when working with delicate or highly finished materials where surface damage should be minimized. In such cases, alternative methods like collets or other specialized workholding devices may be more appropriate.

How do I properly attach and use a lathe dog?

Attaching and using a lathe dog is a relatively simple process. To attach the dog, loosen the lathe machine’s chuck or collet, slide the dog onto the workpiece, and tighten the chuck or collet securely. Make sure the dog’s teeth grip the workpiece firmly. Fasten the dog’s set screws, if provided, to provide additional security.

Once the lathe dog is attached, you can start the lathe machine’s motor, which will rotate the workpiece with the help of the dog. Remember to always use proper safety precautions and follow the manufacturer’s guidelines when operating the lathe machine and using the lathe dog. It’s also essential to periodically inspect the dog for any signs of wear or damage and replace it if necessary to ensure reliable and safe operation.

How to machine between center’s using lathe dog

Summary

So, let’s wrap things up! A lathe dog is a handy tool used with a lathe machine. It helps hold the workpiece firmly in place, preventing it from slipping. This improves accuracy and makes it easier to make precise cuts or shapes. A lathe dog can also be adjusted to work with different-sized workpieces. It is an essential tool for anyone working with a lathe machine, especially for turning long or irregularly shaped materials. So, if you want to get the best results from your lathe machine, using a lathe dog is definitely worth considering!

source https://thehabitofwoodworking.com/2023/why-use-a-lathe-dog/

No comments:

Post a Comment